Make Sure Optimum Efficiency: Picking the Right Komatsu Undercarriage Parts for Your Fleet

Make Sure Optimum Efficiency: Picking the Right Komatsu Undercarriage Parts for Your Fleet

Blog Article

Explore Undercarriage Parts for Your Equipment Needs

Keeping the undercarriage of your equipment is a vital facet often ignored up until problems arise. From excavators to bulldozers, the undercarriage plays an important duty in the general efficiency and durability of hefty tools. Recognizing the parts that comprise the undercarriage and the relevance of picking the right parts is vital to ensuring smooth operations and cost-efficient upkeep. As we discover the globe of undercarriage components for equipment demands, a deeper understanding right into the details of this essential system will unfold, dropping light on the structure that supports the performance of your tools.

Importance of Undercarriage Maintenance

Normal upkeep of undercarriage components is essential for making certain ideal performance and long life of equipment. The undercarriage of heavy tools, such as excavators, excavators, and track loaders, plays an important role in sustaining the weight of the equipment, providing stability on various terrains, and enabling smooth operation - komatsu undercarriage parts. Ignoring undercarriage upkeep can cause costly fixings, lowered performance, and potential safety and security risks

Routine evaluations of undercarriage parts, such as track chains, gears, idlers, and rollers, are important to identify deterioration at an early stage. Attending to issues immediately can protect against more damage to the undercarriage and various other components of the equipment. Appropriate cleaning of undercarriage components is also necessary to get rid of dirt, debris, and various other contaminants that can increase wear and rust.

Routine lubrication of undercarriage components is another essential element of upkeep to make certain smooth motion and reduce rubbing in between elements. In addition, tracking the usage hours and keeping maintenance documents can help in scheduling prompt replacements and prolonging the overall life expectancy of the equipment. By focusing on undercarriage upkeep, devices owners can maximize efficiency, lessen downtime, and ultimately save money on repair service prices over time.

Sorts Of Undercarriage Components

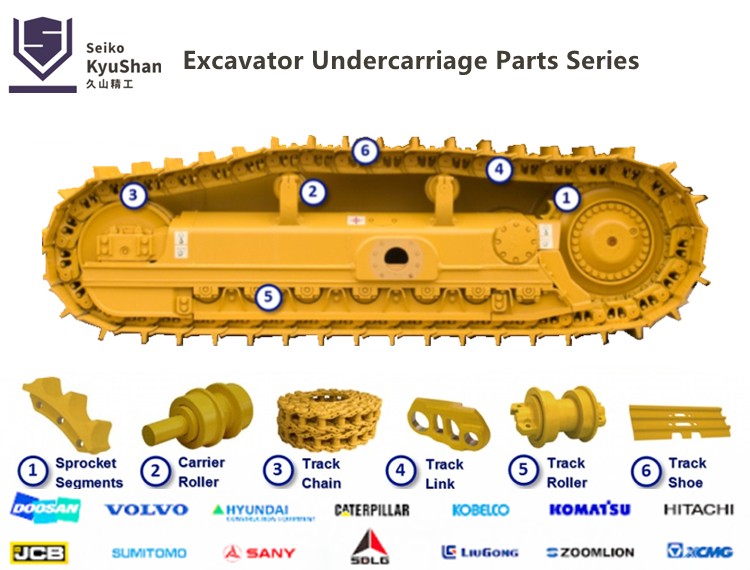

Upkeep of undercarriage components is essential for machinery durability; understanding the various types of undercarriage elements is crucial for effective upkeep methods. Undercarriage parts differ relying on the type of machinery and its desired usage. Common kinds of undercarriage parts consist of track chains, track shoes, rollers, idlers, sprockets, and track frameworks.

Track chains are in charge of moving the equipment ahead and sustaining the weight of the tools. Track footwear offer traction and secure the track chain from deterioration. Rollers help in weight circulation and track assistance, while idlers aid preserve appropriate track tension. Gears involve with the track chain and transfer power to move the machinery. Ultimately, track frameworks work as the structure for the whole undercarriage setting up, linking all the components with each other.

Routine examination and upkeep of these undercarriage components are vital to avoid pricey fixings and downtime. By recognizing the feature of each kind of undercarriage part, equipment drivers visit this site right here can ensure optimum performance and expand the life-span of their devices.

Variables to Take Into Consideration When Choosing Parts

One more essential factor is compatibility with the details equipment model. Each item of machinery may have one-of-a-kind needs for undercarriage components, including dimension, layout, and specs. Making certain that the components are suitable with the equipment will certainly aid avoid operational concerns and early wear.

Furthermore, it is necessary to take into consideration the operating conditions in which the machinery will certainly be used. Elements such as terrain, weather problems, and usage frequency can all affect the damage on undercarriage components. Choosing parts that are developed to stand up to the specific operating conditions can help extend the life of the equipment and minimize upkeep costs over time.

Benefits of High-Quality Undercarriage Parts

High-grade undercarriage components play a crucial role in boosting equipment performance and expanding its functional longevity. By purchasing first-class undercarriage components, equipment drivers gain from enhanced sturdiness and integrity. One of the primary advantages of utilizing high-grade undercarriage components is enhanced effectiveness. These parts are designed to hold up against heavy lots, extreme surfaces, and demanding functioning conditions, making certain that the equipment runs at its optimal level without frequent failures or breakdowns.

Additionally, high-quality undercarriage parts add to cost financial savings in the future. While the initial investment might be higher contrasted to conventional parts, the longevity and durability of premium parts lower useful site the need for constant replacements and repair services. This not only lessens downtime yet likewise reduces upkeep expenses, ultimately leading to greater total performance and profitability for organizations that depend on heavy equipment.

Additionally, remarkable undercarriage parts boost safety and security by decreasing the danger of unexpected failings or crashes. The raised security and efficiency supplied by high-grade elements develop a more secure working atmosphere for machinery drivers and those working in close proximity to the equipment. Inevitably, selecting top quality undercarriage components is a critical decision that generates numerous advantages in regards to efficiency, longevity, cost-efficiency, and security.

Tips for Extending Undercarriage Life Expectancy

To take full advantage of the durability of undercarriage components for equipment, carrying out aggressive treatment practices is vital for guaranteeing optimum performance and sturdiness. Consistently checking the undercarriage components for indications of wear and tear, such as damaged tracks, loose bolts, or damaged rollers, is critical. Attending to these problems immediately can protect against additional damage and expand the lifespan of the undercarriage. Furthermore, preserving appropriate track stress is crucial to lower premature endure the elements. Over-tightened tracks can cause boosted tension on the undercarriage, while loosened tracks can trigger imbalance and uneven wear.

Running the equipment within recommended guidelines, such as staying clear of too much speeds or overloading, can also add to expanding the undercarriage life-span. By following these suggestions, equipment owners can make sure optimal efficiency and resilience of their undercarriage parts.

Verdict

In final thought, keeping the undercarriage components of equipment is critical for optimal performance and long life. Investing in top notch undercarriage parts not just boosts performance yet additionally reduces downtime great site and pricey repairs.

Regular maintenance of undercarriage parts is crucial for ensuring ideal efficiency and durability of machinery.Maintenance of undercarriage parts is necessary for equipment long life; recognizing the different types of undercarriage components is vital for efficient upkeep techniques.When picking undercarriage components for machinery, it is critical to think about different variables to ensure optimal efficiency and longevity.To optimize the longevity of undercarriage components for machinery, executing positive treatment practices is essential for making certain optimum efficiency and resilience. By following these tips, machinery owners can make certain optimal performance and durability of their undercarriage components.

Report this page